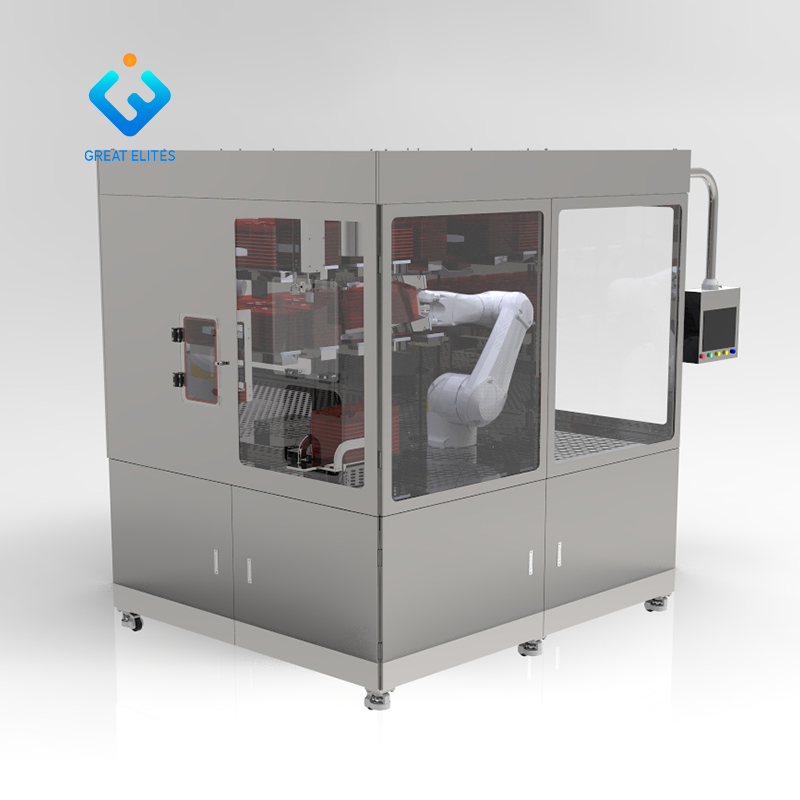

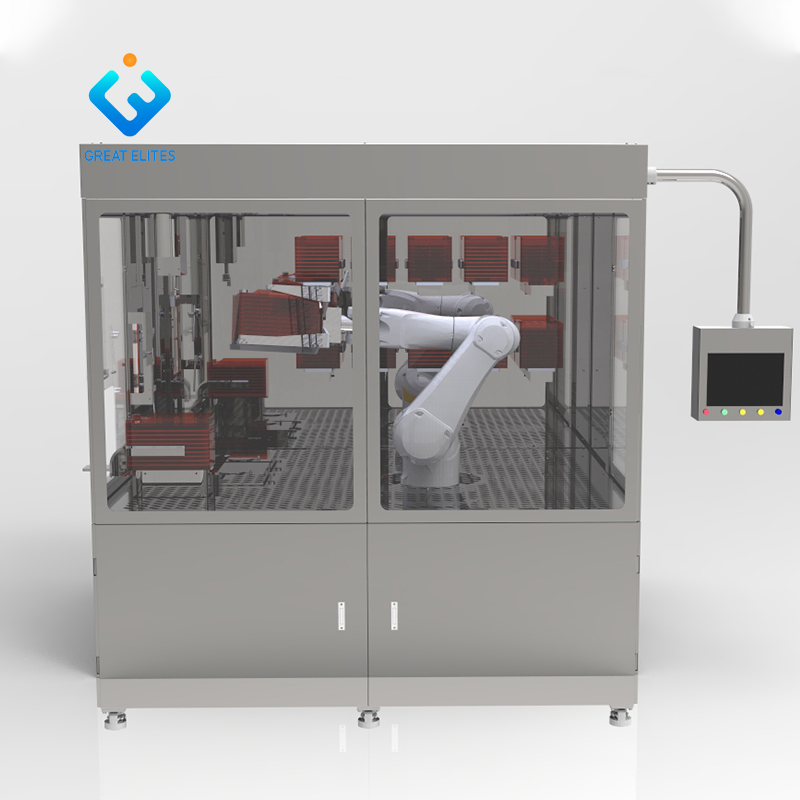

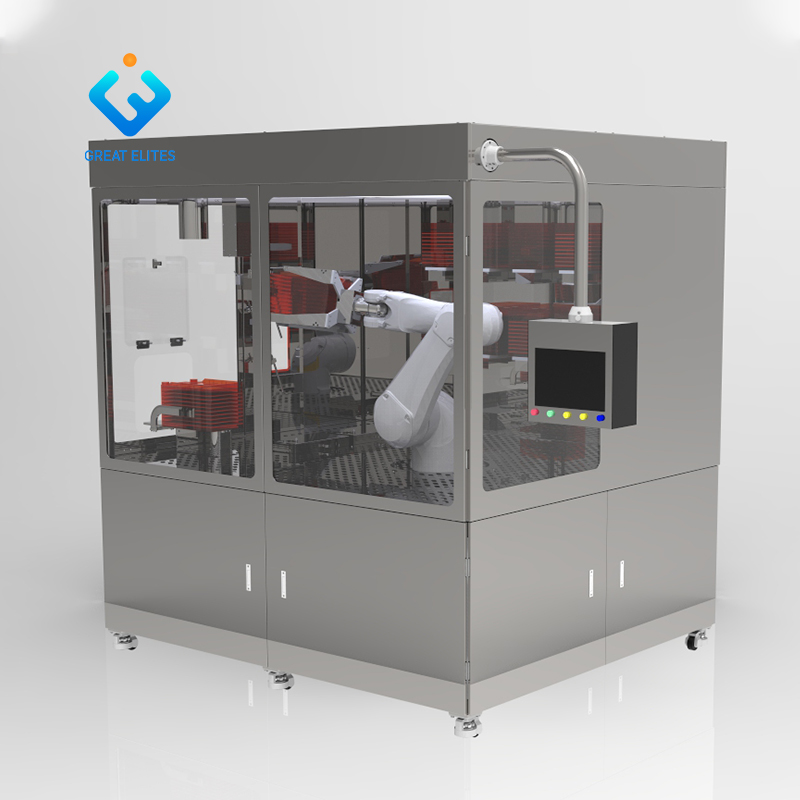

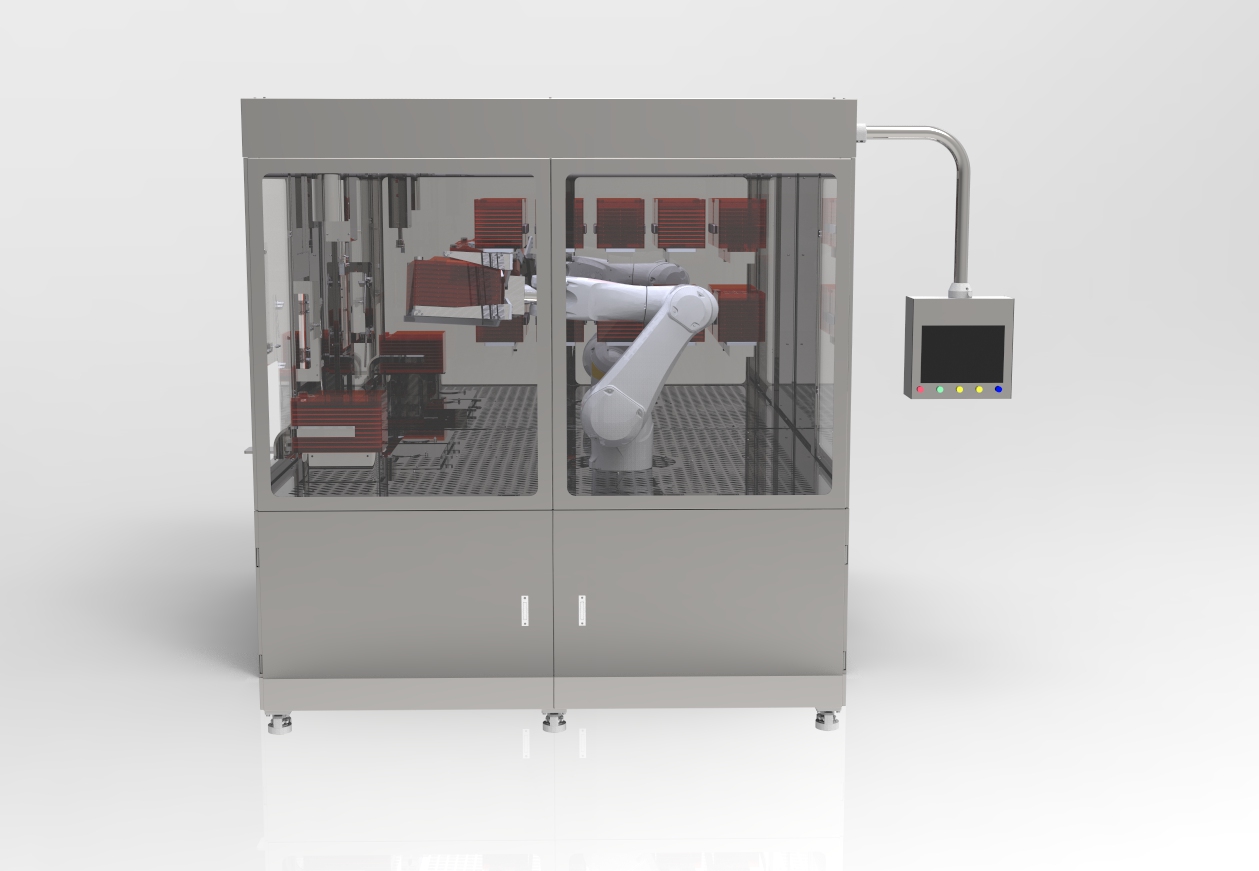

GMP Compliant Cell Workstation Automatic Cell Culture

Brand GREAT ELITES

Product origin CHINA

Delivery time 6 month

Supply capacity 50 sets per year

GMP compliant cell workstation automatic cell culture, flexible program setting, unmanned equipment operation process, one key switching formula in the program, meeting a variety of process operation types, suitable for laboratory types, small space and smaller body.

The introduction of GMP compliant cell workstation automatic cell culture

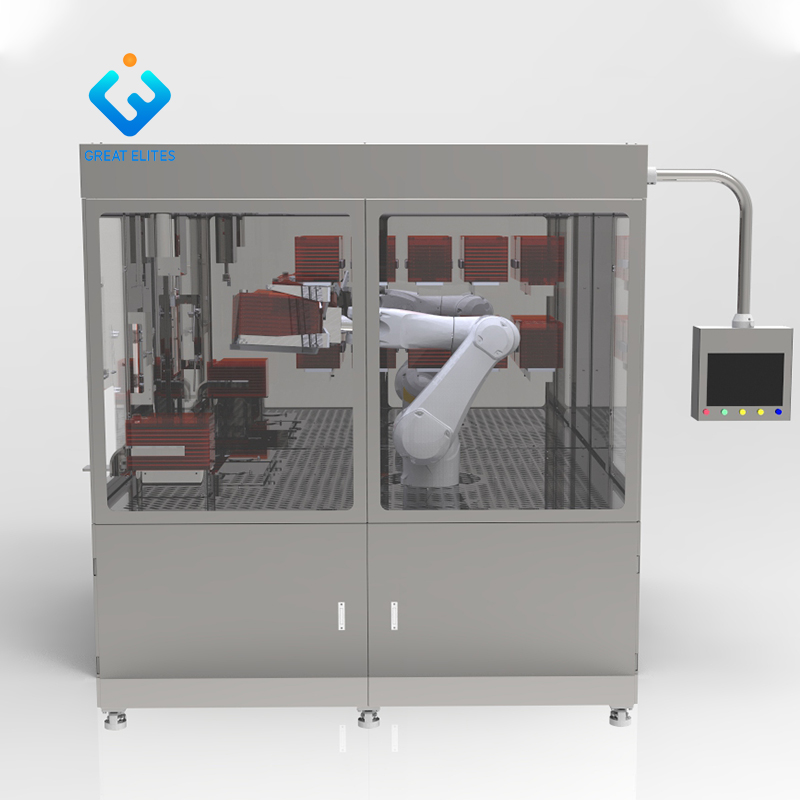

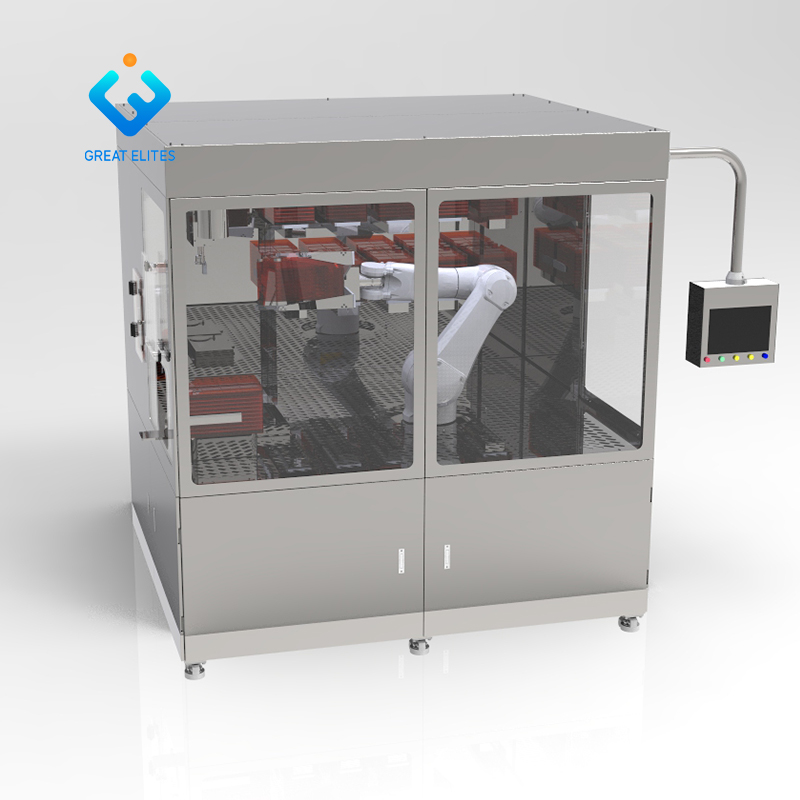

GMP Compliant Cell Workstation Automatic Cell Culture, flexible program setting, unmanned equipment operation process, one key switching formula in the program, meeting a variety of process operation types, suitable for laboratory types, small space and smaller body.

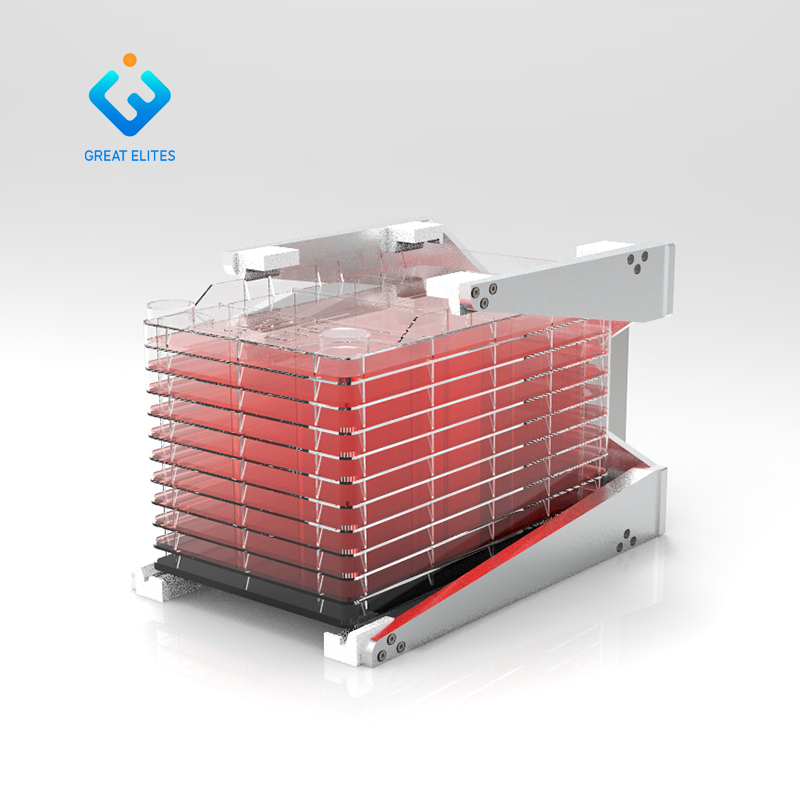

The main frame is mainly used for placing multi-layer cell culture containers; The lifting mechanism is used for lifting multi-layer containers to facilitate observation of the bottom of the container; The upper and lower digital microscope system is mainly used to observe the upper and lower surfaces of multi-layer containers, so as to output high-definition images to the display. The equipment is suitable for high efficiency requirements, mass production of vaccine, stem cell production enterprises.

The characteristics of GMP compliant cell workstation automatic cell culture

1. Save manpower

The efficiency of manual cell handling plant is low and the safety is poor. The robot handling system has high degree of automation, sustainable operation, significantly improved efficiency and good safety.

2. Simple operation

The production process is automatically controlled by program without manual intervention. The whole process only needs the operator to place the cell factory on the entrance platform.

3. Real time data upload

The controller reserves communication interfaces, including Ethernet, MODBUS, PROFINET and other communication interfaces, which can upload production related data to the production data center.

4. Cost saving

Due to the high labor cost in the production process, the equipment adopts robot operation, which can effectively save the cost of human resources and save the site.